en

en

Home > Aviation > Products > Greases, lubricants, oils and special fluids > AeroShell

Turbine oils

Piston Engine Oils

Product Description

AeroShell Turbine Oil 2 is a 2 mm 2/s mineral turbine oil blended from mineral base stocks to which a pour-point depressant and an anti-oxidant have been added.

Main Applications

- AeroShell Turbine Oil 2 is widely used for inhibiting fuel systems and fuel system components during storage.

- AeroShell Turbine Oil 2 is an analogue to the Russian Grade MK-8 and can therefore be used in engines which require the use of MK-8.

Features, Specifications and Approvals

- Approved MIL – PRF – 6081D Grade 1010 (US)

- Equivalent to AIR 3516/A (French)

- Analogue to MK-8 (Russian) · NATO Code O-133

- Joint Service Designation OM-10 (Obsolete).

Product Description

AeroShell Tubine Oil 3 is a 3 mm²/s mineral turbine oil blended from mineral base stocks to which an anti-corrosion additive has been added.

Main Applications

- AeroShell Turbine Oil 3 was developed for early pure jet engines and is still approved for some versions of these engines plus the Turbomeca Astazou, Artouste, Turmo, Bastan and Marbore engines.

- AeroShell Turbine Oil 3 is widely used for inhibiting fuel systems and fuel system components during storage.

- AeroShell Turbine Oil 3 is an analogue to the Russian Grade MK-8 and can therefore be used in engines which require the use of MK-8. It is also used as the mineral turbine oil component in the mixture of mineral turbine oil and piston engine oil used in Russian turbo-prop engines.

Features, Specifications and Approvals

- Approved DEF STAN 91-99 (British)

- Equivalent to AIR 3515/B (French)

- Analogue to MK-8 (Russian)

- NATO Code O-135

- Joint Service Designation OM-11.

Product Description

AeroShell Turbine Oil 3SP is a 3 mm²/s mineral turbine oil incorporating additives to improve anti-wear and anti- oxidant properties as well as low temperature properties.

Main Applications

- AeroShell Turbine Oil 3SP has excellent low temperature properties and is approved for use in Russian engines which use the Russian grades MS-8P, MK-8P and MS-8RK. Typical civil applications include various models of the Il-62, Il-76, Il- 86, Il-114, Tu-134, Tu-154, YAK-40, AN-12, AN-26, AN-30, and M-15 aircraft as well as the Mi-6 and Mi-10 helicopters.

Typical military applications include the MiG-9, MiG-11, MiG-15, MiG-17, MiG-21, Su-7, Su-9, Su-11 and Su-15 aircraft.

AeroShell Turbine Oil 3SP is approved for use in the preservation of oil and fuel systems where Russian grades MK- 8, MS-8P and MS-8RK are used.

AeroShell Turbine Oil 3SP can also be used in oil mixtures where this oil is mixed with piston engine oil. Typical mixtures are:

- SM-4.5:

= 75% MS-8P + 25% MS-20

= 75% AeroShell Turbine Oil 3SP + 25% AeroShell Oil 100

- SM-8.0:

= 50% MS-8P + 50% MS-20

= 50% AeroShell Turbine Oil 3SP + 50% AeroShell Oil 100

- SM-11.5:

= 25% MS-8P + 75% MS-20

= 25% AeroShell Turbine Oil 3SP + 75% AeroShell Oil 100

Typical applications for these mixtures include the Il-8, AN-12, AN-24, AN-26, AN-28 and AN-30 aircraft as well as various military aircraft and some helicopter transmissions.

Features, Specifications and Approvals

Tested and approved by the Central Institute of Aviation Motors (CIAM) in Moscow:

- MS-8P (OST 38.01163-78)

- MS-8RK (TU 38-1011181-88)

- MK-8 (GOST 6457-66)

- MS-8P

- MS-8R

AeroShell Turbine Oil 3SP is also approved and ratified in Decision No DB – 6.8 – 21 by:

- GUAP Goscomoboronprom (Chief Department of Aviation Industry of Defence Industry State Committee of Russian Federation)

- DVT MT (Aviation Transport Department of Ministry of Transport of Russian Federation).

О

Product Description

AeroShell Turbine Oil 308 is a 3 mm²/s synthetic ester oil incorporating additives to improve resistance to oxidation and corrosion and to minimise wear.

Main Applications

- AeroShell Turbine Oil 308 was developed specifically for use in particular models of aircraft turbo-prop and turbo-jet engines for which a MIL-PRF-7808 (formerly MIL-L-7808) oil is required.

- AeroShell Turbine Oil 308 contains a synthetic ester oil and should not be used in contact with incompatible seal materials and it also affects some paints and plastics.

Features, Specifications and Approvals

- Approved MIL – PRF – 7808L Grade 3 (US)

- NATO Code O -148

- Joint Service Designation OX – 9.

Product Description

AeroShell Turbine Oil 390 is a 3 mm²/s synthetic diester oil incorporating a carefully selected and balanced combination of additives to improve thermal and oxidation stability and to increase the load carrying ability of the base oil.

Main Applications

AeroShell Turbine Oil 390 was developed primarily as an improved 3 mm²/s oil for British turbo-jet engines. AeroShell Turbine Oil 390 is fully approved for a wide range of turbine engines.

More recently, because of the low temperature characteristics of AeroShell Turbine Oil 390, there is interest in using this oil in auxiliary power units (APU) in order to overcome the effects of cold soak. Normal practice is to shut down the APU during cruise, the APU then experiences cold soak, often prolonged, and when the unit is started there is considerable difficulty resulting in the unit not coming up to speed in the given time, thus causing a hung start.

In such cases where the APU is subject to a long cold soak the viscosity of standard 5 mm 2 /s oils used in the APU will increase from 5 mm 2 /s at 100 0 C to typically 10,000 mm 2 /s at –40 0 C. At this much higher viscosity the oil cannot flow easily leading to a large viscous drag within the APU, thereby contributing to the difficulty in starting. AeroShell Turbine Oil 390 on the other hand experiences a much smaller viscosity increase (typically 2000 mm 2 /s at –40 0 C) with a reduction in viscous drag which is often sufficient to overcome hung start problems.

All experience to date shows a considerable improvement in cold reliability of the APU when AeroShell Turbine Oil 390 is used.

Features, Specifications and Approvals

- Approved DEF STAN 91-94 (British)

- Analogue to IPM -10, VNII NP 50-1 4f and 4u, and 36Ku-A (Russian)

- Joint Service Designation OX-7

- Honeywell : GTCP 30, 36, 70, 85, 331 and 660 APUs Starters, Turbo Compressors

- Pratt & Whitney Canada : PW901A APU · Rolls Royce : Conway, Spey, Tay, M45H

- Turbomeca : Astazou, Artouste, Bastan VII, Marbore 6, Makila, Turmo

- Hamilton-Sundstrand: APS 500, 1000, 2000, 3000.

О

Product Description

AeroShell Turbine Oil 500 is a 5 mm2/s synthetic hindered ester oil incorporating a carefully selected and balanced combination of additives to improve thermal and oxidation stability and metal passivation.

Main Applications

- AeroShell Turbine Oil 500 was developed essentially to meet the requirements of Pratt & Whitney 521 Type II and MIL-L- 23699 specifications and is entirely suitable for most civil and military engines requiring this class of lubricant. AeroShell Turbine Oil 500 is approved for use in a wide range of turbine engines as well as the majority of accessories.

- With the advent of the new civil turbine oil specification, SAE AS5780, which has more stringent requirements than the military specification MIL-PRF-23699, AeroShell Turbine Oil 500 was approved as a SPC (Standard Performance Capability) oil. AeroShell Turbine Oil 500 contains a synthetic ester oil and should not be used in contact with incompatible seal materials and it also affects some paints and plastics.

Features, Specifications and Approvals

AeroShell Turbine Oil 500 is approved for use in all models of the following engines:

- Honeywell : TFE 731, TPE 331, GTCP 30, 36, 85, 331, 660 and 700 series APUs. ALF 502, LF507, LTS101, LTP101, T53, T55, AL5512

- Allison (Rolls-Royce) : 250 Series, 501 D13, T56, GMA 2100, GMA 3007

- BMW- Rolls-Royce : BR710, BR715 · GE 90, CF6, CT58, CF700, CJ610, CJ805, CF34, CT7, CT64

- Pratt & Whitney : JT3, JT4, JT8, JT9, JT12, PW4000, PW6000 · Pratt & Whitney, Canada : JT15, PT6A, PT6T, ST6, PW100, PW200, PW300, PW500

- Rolls-Royce : Tay, Gnome, Spey, RB183, Adour, M45H, Viper (Series MK 301, 521, 522, 526, 535, 540, 601, 623 and 632)

AeroShell Turbine Oil 500 is also approved for use in the industrial and marine versions of the Rolls Royce Trent, Avon, Allison 501K and 570K, Honeywell TF35, Pratt & Whitney GG3/FT3, GG4/FT4, GG12/FT12, all General Electric LM Series of units, Turbomeca industrial engines and certain Solar gas turbine engines.

Product Description

AeroShell Turbine Oil 555 is an advanced 5 mm²/s synthetic hindered ester oil incorporating a finely balanced blend of additives to improve thermal and oxidation stability and to increase the load carrying ability of the base oil.

Main Applications

- AeroShell Turbine Oil 555 was specifically developed to meet the high temperatures and load carrying requirements of SST engines and the DEF STAN 91-100 (formerly DERD 2497) and XAS-2354 specifications. AeroShell Turbine Oil 555 was also designed to give enhanced performance in current engines.

- More recently with the need to transmit more power and higher loads through helicopter transmission and gearbox systems (many helicopters use a synthetic turbine engine oil in the transmission/gearbox system) it has become apparent that the use of a very good load carrying oil, such as AeroShell Turbine Oil 555 is necessary. This in turn has led to the development of a U.S. Military Specification, DOD-L-85734, which covers a helicopter transmission oil against which AeroShell Turbine Oil 555 is fully approved. · AeroShell Turbine Oil 555 contains a synthetic ester oil and should not be used in contact with incompatible seal materials and it also affects some paints and plastics.

Features, Specifications and Approvals

- Approved DOD-PRF-85734A (US)

- Approved DEF STAN 91-100 (British)

Note: both UK and US production are manufactured to the same formulation.

- NATO Code O-160

- Joint Service Designation OX-26

- Pratt & Whitney : Approved 521C Type II

- General Electric : Approved D-50 TF 1

- Allison : Approved EMS-53 (Obsolete)

- AeroShell Turbine Oil 555 is approved for use in all models of the following engines:

- Honeywell : Auxiliary Power Units GTCP 30, 36, 85, 331, 660 and 700 series

- General Electric : CT58, CT64, CF700, CJ610

- Motorlet : MD601D, E and Z

- Pratt & Whitney : JT3, JT4, JT8, JT9, JT12, PW4000

- Pratt & Whitney Canada : ST6, PW200

- Rolls-Royce : Gem, Gnome, M45H, Olympus 593, RB199

- Turbomeca : Adour

AeroShell Turbine Oil 555 is approved for an increasing number of helicopter transmissions, whilst details are listed below, it is important that operators check latest status with the helicopter manufacturer. In all cases it is important to check compatibility with seals used in the transmission/ gearbox.

- US Military : Approved for helicopter transmission specification DOD-PRF-85734A

- Eurocopter : Approved for Super Puma, for other helicopters check with Eurocopter

- Agusta : Approved for A109 and A129 models, for other models check with Agusta

- Bell Helicopter Textron : Approved for all Bell turbine engined powered helicopters

- Boeing Vertol : Approved for Chinook · McDonnell Douglas : Approved · MBB : Approved

- Sikorsky : Approved for S-61N (note other types such as the S-70 and S-76 do not use synthetic turbine oils in the transmission)

- Westland Helicopters : Approved for some models.

Product Description

AeroShell Turbine Oil 560 is a third generation, high performance, low coking 5 mm²/s synthetic hindered ester oil incorporating a carefully selected and finely balanced combination of additives to improve thermal and oxidation stability.

Main Applications

Changes which have taken place over the last twenty years in engine performance (in terms of improved fuel consumption, higher operating temperatures and pressures) and maintenance practices have resulted in increased severity in lubricant operating conditions.

AeroShell Turbine Oil 560 was developed to withstand the hostile environments of today’s high powered, high compression engines in which the older generation of oils can be stressed up to and beyond their thermal limits, as evidenced by oil coking in the high temperature bearing areas.

By overcoming the problems associated with using old technology oils in new technology engines, AeroShell Turbine Oil 560:

- maintains a cleaner engine

- provides improved load carrying capacity

- reduces maintenance costs

- prolongs bearing life in both new and existing engines.

In order for military authorities to take advantage of this better performance in military engines the specification MIL-PRF- 23699 was re-written to include a “High Thermal Stability” (HTS) grade as well as the Standard (STD) and Corrosion Inhibited (C/I) grades. AeroShell Turbine Oil 560 is fully approved as an HTS oil. With the advent of the new civil turbine oil specification, SAE AS5780, which has more stringent requirements than the military specification, AeroShell Turbine Oil 560 was approved as a SPC (Standard Performance Capability) oil.

With effect from January 1st 2002, AeroShell Turbine Oil 560 has been manufactured with an improved formulation to further enhance its anti-coking performance.

AeroShell Turbine Oil 560 contains a synthetic ester oil and should not be used in contact with incompatible seal materials and it also affects some paints and plastics.

.Features, Specifications and Approvals

- Approved MIL – PRF -23699G Grade HTS (US) Approved SAE AS5780B Grade SPC

- Equivalent DEF STAN 91-101 (British)

- Equivalent DCSEA 299/A (French)

- Analogue to VNII NP 50-1-4F, B3V, LZ-240, VNII NP 50-1-4U and 36/Ku-A (Russian)

- NATO Code O-154

- Joint Service Designation : Equivalent OX-27

- Pratt & Whitney : Approved 521C Type II

- General Electric : Approved D-50 TF1

- Allison : Approved EMS-53 (Obsolete)

- COMAC Approved to QPL-CMS-OL-202

AeroShell Turbine Oil 560 is approved for use in all models of the following engines:

- Honeywell : TFE 731, TPE 331, APUs (majority of models), LTS 101, LTP 101, ALF 502, LF 507, AS907, AS977, GTCP 30, 36, 85, 331, 660, RE220

- Allison (Rolls-Royce) : 250 Series

- BMW – Rolls-Royce : BR710, BR715

- CFM International : CFM 56 (all models) · CFE 738

- Engine Alliance: GP7200

- GE 90, CF6 (all models), CJ610, CF700, CT34, GEnX

- IAE : V2500 Series

- IHI : FJR 710

- Hamilton Sundstrand : APS 500, 1000, 2000, 3000

- Pratt & Whitney : JT3D, JT8D, JT9D, PW4000 Series (cleared for flight evaluation in PW2000 engines)

- Pratt & Whitney Canada : PT6T, PT6A (some models only), PW120,121 Series, JT15D, PW200 Series, PW300 Series, PW500 Series, PW901A APU

- Rolls-Royce : Spey, Tay RB183, Adour, RB199

- Turbomeca : Arriel, Arrius, Makila, RTM 322, TM 319, TM 333, TP 319, MTR 390, various models of Astazou and Artouste engines.

Main Applications

AeroShell Turbine Oil 750 was developed to meet the requirements of DERD 2487 (now DEF STAN 91-98) and to provide a high standard of lubrication in British civil gas turbines, particularly turbo-prop engines where a good load carrying oil was required for the propeller reduction gearbox.

AeroShell Turbine Oil 750 is also approved by the Russian authorities as an analogue to MN-7.5u and for those Russian turbo-prop applications which require the use of mixtures of mineral turbine oil and aircraft piston engine oil.

AeroShell Turbine Oil 750 contains a synthetic ester oil and should not be used in contact with incompatible seal materials and it also affects some paints and plastics.

Features, Specifications and Approvals

- Approved DEF STAN 91- 98 (replaces DERD 2487) (UK)

- Equivalent AIR 3517A (French)

- Analogue to TU 38.1011722- 85 Grade MN-7.5u (Russian)

- NATO Code O-149 (equivalent O -159)

- Joint Service Designation OX-38

AeroShell Turbine Oil 750 is approved for use in all models of the following engines:

- Honeywell : Auxiliary Power Units (some models)

- Pratt & Whitney Canada : PT6 (some models)

- BMW-Rolls-Royce : Dart, Tyne, Avon (some early models only), Gnome, Pegasus, Palouste, Nimbus, Proteus, Orpheus, Olympus 200 and 300

- Sikorsky : S-61N transmissions

- Soloviev : D30 engine.

Product information

AeroShell Oil Sport Plus 4 was created in partnership with Rotax and works with such engines as the Rotax 912, 914 and 915 series. Its improved formulation, which blends high-quality hydrocarbon base stocks and incorporates synthetic technology, works well with the low cylinder head temperature compared to air-cooled engines, low oil consumption, and engine internals possessed by these kinds of aircraft.

Features:

First specific oil for Light Sport and Very Light/Ultra light aircraft engines

Promotes engine cleanliness

Helps keep engines sludge and varnish free

Helps reduce oil consumption

Helps engines reach TBO (Time Between Overhaul)

Protects highly stressed engines parts against scuffing and wear

Anti-foaming additives to maximise lubrication effectiveness – especially for those engines operating an integrated gearbox

Better cold flow characteristics for easier starts and quicker protection

High thermal stability for longer-lasting and safer lubrication

Can be used in any climate

Advanced anti-rust and anti-wear package

Aviation Oil

Specifications, Approvals & Recommendations:

API SL

JASO MA

VW 502 00

Fully Approved All ROTAX 912 914 Series engines.

Product information

The straight mineral AeroShell Oils 65, 80, 100, and 120 offer protection for a wide variety of ambient take-off temperatures. With their specially blended high-viscosity index base oils, they provide more effective protection to engine components compared to conventional mineral oils, ensuring your aircraft performs reliably between scheduled overhauls.

Each of the numbers of these AeroShell oils represent their viscosity grades, which correspond with the viscosity of the oil at 210°F in Saybolt Universal Seconds.

The relevant grades are approved for use in 4-stroke (4-cycle) certified aircraft and their piston engines, except for Porsche. They’re also approved for other aircraft radial engines that use oil to specification SAE J1966 (MIL-L-6082) and don’t need oils that contain a dispersant additive.

For AeroShell Oils 65, 80, 100, and 120, their main use is during the break-in of new or recently overhauled four-stroke aviation piston engines. However, the lubrication recommendations and duration of break-ins vary depending on the engine, so check with the original engine manufacturer or overhaul facility what their specific recommendations are.

AeroShell Oils 65, 80, 100, and 120 are straight mineral oils blended from selected high-viscosity index base oils. These oils do not contain any additives except for very small amounts of pour point depressant (which aids to improve fluidity at very low temperatures) and an anti-oxidant.

The above oils are approved for all aviation piston engines of civil aircraft when the use of an oil not containing a dispersant additive is required. However, they should also be used during the break-in of a new aviation piston engine or those recently overhauled.

AeroShell Oils 65, 80, 100, and 120 are produced to meet fully the SAE specification J1966 (Grades SAE 30, 40, 50 and 60 respectively).

AeroShell Oils 65, 80, 100, and 120 product benefits

High-viscosity index base oils used in AeroShell oils maintain their viscosity and protect engine components more effectively under the high shear stresses that an engine places on lubricants.

Approved for all reciprocating engines of civil aircraft used for running-in operations or older generation engines requiring non-additive type engine oils (refer to manufacturer recommendations).

Provides compatibility with other approved aircraft piston engine oils. Since AeroShell Oils 65, 80, 100, and 120 are fully approved to SAE J1966 and are listed on the relevant Qualified Products List (QPL), elaborate precautions are not needed when changing from similarly approved aircraft engine oils, as long as these oils are qualified products.

AeroShell oils are inherently stable in storage.

Product information

The W range of AeroShell aircraft oils were the first to use ashless dispersant technology, keeping your engine cleaner. The package of additives within AeroShell Oils W80, W100, and W120 are combined with selected high-viscosity index base stocks to offer exceptional stability, dispersion, and anti-forming performance within the aircraft piston engines for which they’re approved.

Whether you fly for pleasure or your business depends on flight, AeroShell products are designed to help lift your performance.

How to use AeroShell Oils W80, W100, and W120

AeroShell W Oils can be used in four-stroke (four-cycle) certified reciprocating piston engines, including fuel-injected and turbocharged engines. Radial engine operators tend to use AeroShell Oil W120 in warm weather, while AeroShell Oil W100 and AeroShell Oil W 15W-50 should be used in cooler temperatures.

For Lycoming and Continental flat engines, AeroShell Oil W100 or AeroShell Oil W 15W-50 are the most common choices. But AeroShell Oil W80 works brilliantly in place of AeroShell Oil W100 during the colder months.

Check with your engine manufacturer or rebuilder to find out if AeroShell Oils W80, W100, or W120 can be used during break-in. While many engine manufacturers and rebuilders and overhaul agencies say to use straight mineral oils, some say that either ashless dispersant or straight mineral oil can be used for break-in – for example, for Lycoming O-320H and O/LO360E. For all turbocharged Lycoming engines, ashless dispersant oils are recommended for break-in.

AeroShell W Oils shouldn’t be used in automotive engines. If you’re using an automotive engine that’s been converted for use in an aircraft, check with the engine manufacturer to find out which oil you should use.

Single Grade Ashless Dispersant Oils

AeroShell Oils W80, W100, and W120 are ashless dispersant oils specifically developed for aviation piston engines. They reap the performance benefits of combining non-metallic additives with selected high viscosity index base oils. No general rule exists for every engine type when choosing the correct grade of oil; however, based on the average ambient outside temperature at engine start-up, the most common grades are SAE 40, SAE 50, and SAE 60, which equate to AeroShell Oil W80, W100, and W120 respectively.

Traditionally, the choice is associated with climatic zones: AeroShell W80 for cold climate regions (-17 to 21°C), AeroShell Oil W100 for temperate regions (16 to 32°C), and AeroShell Oil W120 for warmer climates (above 26°C)

AeroShell Oils W80, W100, and W120 are produced to meet fully the SAE specification J1899 (Grades SAE 40, 50, and 60 respectively).

Product information

These AeroShell piston engine oils offer the ashless dispersant performance of AeroShell Oils W80 and W100 but with better anti-wear and anti-corrosion than conventional single grade oil, thanks to the same additives for this purpose used in AeroShell Oil W15W-50 Multigrade.

AeroShell Oils W100 Plus and W80 Plus are for pilots who prefer a single grade for the camshaft and lifters but want the extra protection against rust, which proves especially useful when the aircraft is idle. These oils can be used in any Continental Motors liquid-cooled and air-cooled aircraft piston engines.

How to use AeroShell Piston Engine Oils W100 Plus and W80 Plus

Use AeroShell Oils W100 Plus and W80 plus to coat the camshaft and lifters. These piston engine oils include advanced additives that offer better protection against rust and wear than typical single grades, creating a protective barrier that’s especially vital when the aircraft sits idle.

With these oils, there’s less chance of premature damage, and they help the aircraft to reach the recommended time between overhauls.

AeroShell Oil W100 Plus and W80 Plus – The premium single-grade aviation oils.

Single-grade ashless dispersant engine oils

AeroShell Oils W100 Plus and W80 Plus are new single-grade oils that combine proven AeroShell ashless dispersant technology with advanced anti-wear additives. They’re the oils for pilots who want a single grade that delivers extra protection and performance.

The above oils bring together the best qualities of two of the world's best-selling four-cycle aviation oils. They have the single grade, ashless dispersant performance found in AeroShell Oils W100 and W80 and the anti-wear/anti-corrosion additives of AeroShell Oil W 15W-50 Multigrade.

Their single-grade heritage means outstanding resistance to heat, especially in the summer months. Their ashless dispersant formulation helps reduce deposits of harmful metallic ash in combustion chambers. And their advanced additives work against rust, corrosion, and wear in a way no other single grade does. There are simply no better single-grade aviation oils.

AeroShell W100 Plus and W80 Plus product benefits

Superior rust and corrosion protection, giving that extra protection to engine parts that may be susceptible to extreme rusting when an aircraft is not in use. For prolonged periods of non-use, please use AeroShell Fluid 2F.

Improved anti-wear characteristics, particularly at engine start-up. These engine oils also eliminate the need for supplemental additives required by certain Lycoming engines. AeroShell Oil W100 Plus and W80 Plus already contain the Lycoming additive LW 16702 in the correct proportions and meet Lycoming requirements, as well as the US Federal Aviation Authority Airworthiness directive 80-04-03.

Promotes a clean engine. The non-ash forming, polymeric additive was developed to help eliminate the harmful combustion chamber and spark plug deposits that form during normal operation.

High-viscosity index base oils used in AeroShell W oils maintain their viscosity and help protect engine components more effectively under the high shear stresses that an engine places on lubricants.

Provides compatibility with other approved aircraft piston engine oils. Mixing with other products, however, will result in some loss of the superior performance features of AeroShell Oil W100 Plus and W80 Plus.

Product information

Aeroshell Oil W 15 W 50 is a premium semi-synthetic multigrade ashless dispersant oil specifically developed for aviation piston engines. AeroShell Oil W 15 W 50 is a special blend of a high quality mineral oil and synthetic hydrocarbons with an advanced additive package that has been specifically formulated for multigrade applications.

The combination of non-metallic anti-wear additives and selected high viscosity index mineral and synthetic base oils, give exceptional stability, dispersancy and anti-foaming performance. The advanced additive package in AeroShell W 15 W 50 provides excellent protection to engines operating at extreme ambient temperatures. The ashless anti-wear additive package provides exceptional wear protection for camshafts and lifters and other wearing surfaces.

AeroShell W 15 W 50 has become very popular amongst engine manufacturers and operators alike. In order to cater for those Lycoming engines that need improved load carrying, the Lycoming LW 16702 antiwear additive has been incorporated into the formulation thus eliminating the need for supplemental additive addition.

Product Benefits:

Promotes Engine Cleanness. The non-ash forming, polymeric additive was developed to help eliminate the harmful combustion chamber deposits that occur during normal operation.

Multigrade Performance allows for improved engine operation in temperature extremes.

Excellent Low Temperature characteristics provide easier cold weather starting and rapid lubrication of engine parts.

Reduces Oil Consumption in some cases by up to 50% and resists thickening at low temperatures.

Protects against oil cooler plugging.

All Season oil function since there is no need to change from a winter / summer grade depending on the ambient temperatures.

High Viscosity Index Semi-Synthetic Base Oils used, maintain their viscosity and help protect engine components more effectively under the high shear stresses that an engine places on lubricants.

Provides Compatibility with other approved aircraft piston engine oils. Since AeroShell Oil W 15W-50 is fully approved to SAE J-1899 and is listed on the relevant Qualified Products List (QPL), elaborate precautions are not needed when changing from similarly approved aircraft engine oils, as long as these oils are qualified products.

Reduces Fuel Consumption by up to 5% over straight grade engine oils.

Product information

AeroShell Oil Diesel Ultra is unique in being the only fully synthetic engine oil available in General Aviation.

AeroShell Oil Diesel Ultra is a fully synthetic, multigrade engine oil designed for use in the new generation of compression ignition (Diesel) Aviation Piston Engines. The formulation has been selected to be suitable in piston engines fuelled by Jet A or Jet A-1 and is designed for use in the latest highly rated turbocharged diesel engines under all operating conditions. AeroShell Oil Diesel Ultra must not be used in spark ignition, or Avgas powered aircraft engines.

Applications

AeroShell Oil Diesel Ultra is unique in being the only fully synthetic engine oil available in General Aviation. It also contains unique Shell approved additives to provide superior piston cleanliness and help provide a clean, efficient and reliable engine. These additives include a powerful surface acting additive, which bonds to the surface of highly loaded engine parts, protecting the engine from scuffing damage.

AeroShell Oil Diesel Ultra has been developed to be suitable for use in engines burning Jet fuel and its performance has been designed to cope with the demands of this type of engine. Its key performance features include the ability to sustain high bearing loads, neutralisation of acid build up from the sulphur present in the fuel and high dispersancy to allow for the relatively high particle loading produced when burning Jet fuel.

Hydraulic Fluids

Greases

Detailed Product Description

AeroShell Fluid 4 is intended for use as a hydraulic fluid in undercarriage retraction mechanisms, flap jacks and control mechanisms, brakes, shock absorbers, automatic pilots, oleo legs, tail wheels, servo units, etc. AeroShell Fluid 4 is also suitable for lubricating de-icing pumps and gearboxes.

AeroShell Fluid 4 should be used in systems with synthetic rubber components and must not be used in systems incorporating natural rubber. The latter systems require castor base fluids with which AeroShell Fluid 4 is not interchangeable.

AeroShell Fluid 4 is compatible with AeroShell Fluids 31, 41, 51, 61 and 71, although it is not recommended that AeroShell Fluid 4 is used in systems which require the use of a superclean fluid nor should it be mixed with superclean fluids for operational reasons.

Chlorinated solvents should not be used for cleaning hydraulic components which use AeroShell Fluid 4. The residual solvent contaminates the hydraulic fluid and may lead to corrosion.

Specifications, Approvals & Recs

-

- Meets MIL-H-5606A (US) (Obsolete – see AeroShell Fluid 41)

- Meets DTD 58.5 (Obsolete - see AeroShell Fluid 41)

- Approved DEF STAN 91.48 Grade Normal (European production only) (British)

- Approved DCSEA 415/A (French)

- Analogue to AMG-10 (Russian)

- NATO CODE H-520 (European production only)

- Joint Service Designation OM-18 (European production only).

Product Information

AeroShell Fluid 31 has a specially designed base stock which imparts a relatively high flash point, excellent low temperature properties and good oxidation and thermal stability. In addition, AeroShell Fluid 31 is formulated with high technology additives to provide oxidation and corrosion resistance, antiwear, and anti-foaming protection.

AeroShell Fluid 31 is superclean filtered to ensure optimum performance in particulate monitored systems. AeroShell Fluid 31 is dyed red. The useful operating temperature range is 40 to +205°C.

Features:

- Synthetic hydrocarbon based aircraft hydraulic fluid

- Improved fire resistance characteristics

- Good oxidation & thermal stability

- Anti-foaming protection

- Provides excellent corrosion resistance

Approved to: *MIL-PRF-83282D.

Details:

- AeroShell Fluid 31

- Aircraft Hydraulic Fluid

Supplied in various sizes

Product Information

AeroShell Fluid 41 is a mineral hydraulic oil manufactured to a very high level of cleanliness and it possesses improved fluid properties.It contains additives that provide excellent low-temperature fluidity as well as exceptional anti-wear, oxidation – corrosion inhibition and shear stability.

In addition, metal de-activators and foam inhibitors are included in this high-viscosity index fluid to enhance performance in hydraulic applications.AeroShell Fluid 41 is dyed red.

Features:

- Excellent low temperature fluidity as well as exceptional anti-wear, oxidation - corrosion inhibition and shear stability

- Metal de-activators and foam inhibitors are included in this high viscosity index fluid to enhance performance in hydraulic applications.

- Capable of wide temperature range operation

- Recommended where use of a "superclean" fluid can contribute to improvements in component reliability, and can be used in aircraft systems operating unpressurised between -54C to 90C and pressurized between -54C to 135C

- Dyed red

Specifications:

- DEF/STAN91-48 OM15

- MIL-PRF-5606J

- OM15 Oil

Product Information

AeroShell Fluid 51 is a synthetic hydrocarbon and ester based fluid for use in hydraulic systems which require reliable operation in extreme low and high temperatures as well as performance outside the capability of traditional MIL-PRF-5606 mineral based fluids.

AeroShell Fluid 51 is formulated with high technology additives to provide oxidation and corrosion resistance, anti-wear, and anti-foaming protection.

AeroShell Fluid 51 is superclean filtered to ensure optimum performance in

particulate monitored systems.

AeroShell Fluid 51 is dyed red.

The useful operating temperature range is –54°C to +135°C.

Application

AeroShell Fluid 51 is recommended for use in aircraft, ordnance and missile systems operating from –54°C to +135°C. This fluid should be considered for use in auto pilots, shock absorbers, brakes, flight control systems, hydraulic servo-control systems and other systems using synthetic elastomer seals. This fluid is especially recommended for use in high altitude aircraft that normally operate with extended loiter times and high endurance levels such as UAVs and ELINT systems.

AeroShell Fluid 51 is a synthetic hydrocarbon oil and should not be used in contact with incompatible seal materials. Refer to the General Notes at the front of this section for further information.

AeroShell Fluid 51 is compatible with AeroShell Fluids 4, 31, 41, 61 and 71 and can be used in systems designed to operate with MIL-PRF-5606, MIL-PRF-6083, MIL-PRF-83282 and MIL-PRF-46170 fluids.

Chlorinated solvents should not be used for cleaning hydraulic components which use AeroShell Fluid 51. The residual solvent contaminates the hydraulic fluid and may lead to corrosion.

Product Information

AeroShell Fluid 61 is designed for use where a fire resistant preservative grade hydraulic fluid is required and is suitable for operational use as well as preservation of components during storage and shipment.

Features

- AeroShell Fluid 61 is designed for use where a fire resistant preservative grade hydraulic fluid is required

- Suitable for operational use as well as preservation of components during storage and shipment.

- AeroShell Fluid 61 has an operating temperature range of 40°C to+204°C

- AeroShell Fluid 61 is compatible with AeroShell Fluids 4, 31, 41, 51 and71.

- AeroShell Fluid 61 is a synthetic oil and should not be used in contact with incompatible seal materials

- Chlorinated solvents should not be used for cleaning hydraulic components which use AeroShell Fluid 61.

- The residual solvent contaminates the hydraulic fluid and may lead to corrosion

Details:

- AeroShell Fluid 61

- Hydraulic Fluid

- 55USG Drum

*MIL-PRF-46170E Type I

Product Information

AeroShell Fluid 71 is a preservative mineral hydraulic fluid of improved cleanliness.

AeroShell Fluid 71 is composed of a mineral base oil with an additive package which results in a product with excellent corrosion preventative properties as well as excellent oxidation stability, and good anti-wear characteristics.

AeroShell Fluid 71 is dyed red.

The useful operating temperature range is –54°C to +121°C.

Applications

AeroShell Fluid 71 is intended for preserving hydraulic equipment in storage from –54°C to

+121°C, and also for use in rig testing of hydraulic components.

AeroShell Fluid 71 should only be used in hydraulic systems employing synthetic rubber

seals suitable for MIL-PRF-5606/DEF STAN 91-48 (AeroShell Fluids 4 or 41) type of fluids.

Refer to General Notes at the front of this section for further information.

AeroShell Fluid 71 is compatible with AeroShell Fluids 4, 31, 41, 51 and 61.

Chlorinated solvents should not be used for cleaning hydraulic components which use AeroShell Fluid 71. The residual solvent contaminates the hydraulic fluid and may lead to corrosion.

Product Information

AeroShell Shock Strut Fluid (SSF) and AeroShell Landing Gear Fluid (LGF) are mineral hydraulic fluids (MIL-PRF-6083 and MIL-PRF-5606 respectively) to which additional additives have been added to improve the extreme pressure characteristics and the fluid’s natural lubricity. The lubricity agent provides a stable thin film layer to the metal surfaces at mild operating conditions. When severe conditions exist (landing/touchdown), the extreme pressure additive supplies the load carrying needed at the metal-to-metal surfaces to prevent the occurrence of such phenomena as "ladder cracking" and "slip stiction" of the piston component of the landing gear.

AeroShell SSF is AeroShell Fluid 71 plus additives.

AeroShell LGF is AeroShell Fluid 41 plus additives.

Applications

AeroShell SSF is recommended for all normal applications whilst the better low temperature properties of AeroShell LGF make it particularly suitable in areas of low temperature operations.

AeroShell SSF and AeroShell LGF are compatible with each other as well as with AeroShell Fluids 4, 41 and 71.

AeroShell SSF and LGF are straw yellow in colour.

AeroShell Grease 5 is a high temperature grease composed of a mineral oil thickened with Microgel, this product is available in various sizes.

AeroShell Grease 6 is approved to *MIL-PRF-24139A. It is a general purpose grease composed of a mineral oil thickened with Micro gel, possessing good all-round properties within a limited range.

Aeroshell Grease 7 is approved to *MIL-PRF-23827C Type II. It is an advanced multi-purpose grease, composed of a synthetic oil thickened with Microgel, possessing good load carrying ability over a wide temperature range. It is inhibited against corrosion and has excellent resistant to water.

AeroShell Grease 14 is approved to *MIL-G-25537C. AeroShell Grease 14 is the leading helicopter multi-purpose grease and is approved by all helicopter manufacturers. Supplied in various sizes.

AeroShell Grease 15 is an extreme temperature range grease, composed of silicone oil with an organic thickener. AeroShell Grease 15 is inhibited against corrosion and oxidation, and possesses excellent high temperature and mechanical stability properties and low evaporation rate. It is water resistant.

The useful temperature range is –73°C to +232°C.

AeroShell Grease 15 has a tendency to bleed and should be stirred before use.

AeroShell Grease 15 has replaced AeroShell Grease 15A.

AeroShell Grease 22 is approved to *MIL-PRF-81322G, *DOD-G-24508A and *DEF STAN 91-52. It is a versatile advanced general purpose grease composed of a synthetic hydrocarbon oil thickened with Microgel, with outstanding performance characteristics.

AeroShell Grease 33 is approved to *BMS 3-33C Type 1, *MIL-PRF-23827C Type I and *IPS 06-09-002-03 is a synthetic universal airframe grease composed of a lithium complex thickened synthetic base oil with corrosion and oxidation inhibitors and load carrying additives.

Aeroshell 64 (formerly AeroShell 33MS) is approved to *MIL-G-21164D. It can help to extend component life and reduce maintenance costs by preventing wear and corrosion.

Lubricating Oils

Gearbox Oils

Product Information

For use as a lubricant where a light anti-freezing oil is required, e.g. On aircraft instruments, gun mounting buffers, hydraulic couplings, controls, door hinges, etc. Also used as a preservative oil for Stromberg carburettors and some fuel systems.

AeroShell Turbine Oil 3 can be used as an alternative to AeroShell Fluid 1, but AeroShell Fluid 1 must never be used as an alternative to AeroShell Turbine Oil 3.

Specifications, Approvals & Recommendations

. Approved DEF STAN 91 -44 (British)

. Equivalent to AIR 3515/B (French)

. NATO Code 0-134

. Joint Service Designation OM-13

Product Information

It is inhibited against oxidation and corrosion. AeroShell Fluid 3 is a relatively low viscosity product with good resistance to evaporation. AeroShell Fluid 3 is recommended for general lubrication of aircraft parts that require a light oil, e.g. hinges, pivot joints, shaft joints, linkage pins and bearings, pulleys, cables, camera mechanisms, radio and radar gear and instruments.

AeroShell Fluid 3 is normally applied by means of an oil can or brush. For this reason it is also described as ‘an oilcan lubricant’. Operating temperature range of AeroShell Fluid 3 is –54°C to +121°C. For high temperature applications where no provision is made for frequent re-lubrication the synthetic oil, AeroShell Fluid 12, should be used in place of the mineral oil, AeroShell Fluid 3; however in this case care should be taken to ensure that there is no incompatibility between AeroShell Fluid 12 and seals, paints etc.

Features:

Low viscosity product

Good resistance to evaporation

For general lubrication of aircraft parts

Operating temperature : –54°C to +121°C.

Specifications: DEF STAN 91-47 MIL-PRF-7870E O-142 OM-12

Product Information

AeroShell Fluid 12 is used for general aircraft lubrication as well as for aircraft gyro instrument gimbal bearings, separately lubricated high speed turbines and compressors, aircraft air cycle equipment and electronic equipment. It is particularly suitable for use when an oil with a low evaporation rate is required at high and low temperatures.

AeroShell Fluid 12 is a synthetic oil and it should not be used in contact with incompatible seal materials such as neoprene or natural rubber. Suitable seal material include Fluorocarbon (Viton). AeroShell Fluid 12 may also affect certain paints and plastics. It is recommended that components are evaluated for compatibility if there is any question.

Features:

Low volatility synthetic ester oil

Used in aircraft instruments

Not be used in contact with incompatible seal materials

Good high & low temperature characteristics

Various sizes available

Details:

AeroShell Fluid 12

Synthetic Ester Oil

Supplied in various sizes

Информация за продукта

AeroShell Fluid 18 е минералното смазочно масло и предлага превъзходна защита от корозия навсякъде, където водата може да влезе в контакт с метални части. Може да се използва за различни приложения, включително авиация, автомобилостроене, индустрия и др. Течността смазва, докато предпазва и може да се използва на закрито или навън. Високо пречистеното смазочно масло на петролна основа работи добре при умерено ниски температури, но не се препоръчва за използване като смазка при изключително ниски температури под -57 градуса C.

Приложения

AeroShell Fluid 18 е за използване при смазване и защита от корозия на малки оръжия и автоматични оръжия и като лубрикант с общо предназначение за всички приложения, където се изисква изместване на вода, защита от корозия и смазване при ниски температури.

AeroShell Fluid 18 е предназначен също за ключалки, панти, електрически двигатели, вентилатори, малки лагери, контролни пръти и кабели и може да се използва в множество неавиационни приложения.

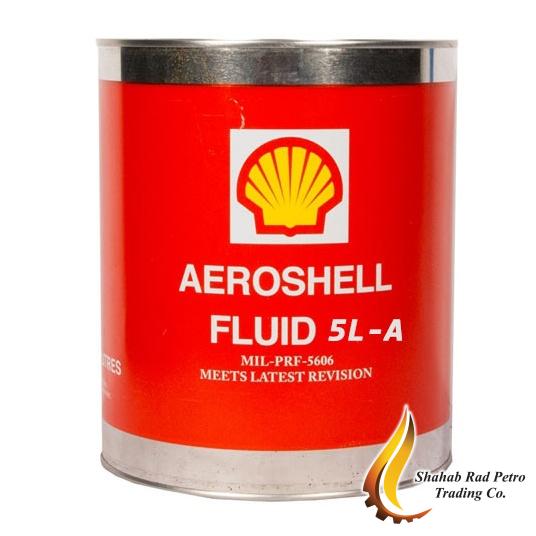

AeroShell Fluid 5L-A and 5M-A are recommended for the lubrication of gears where high tooth loadings exist e.g. helicopter gearboxes and constant speed alternator drives.

AeroShell Fluid 5L-A is of low viscosity, AeroShell Fluid 5M-A of medium viscosity.

![AeroShell Fluid 5M-A [5G Pail]: Amazon.com: Industrial & Scientific](https://m.media-amazon.com/images/I/31HAZrVZ6gL.jpg)

AeroShell Fluid 5L-A and 5M-A are recommended for the lubrication of gears where high tooth loadings exist e.g. helicopter gearboxes and constant speed alternator drives.

AeroShell Fluid 5L-A is of low viscosity, AeroShell Fluid 5M-A of medium viscosity.

AeroShell S.8350 is an extreme pressure Gear Oil supplied in a 20Lt Pail.

Please Note: this product used to be approved to DTD900/4981, but this specification is now obsolete and has been replaced with Joint Services Designation OEP-215.

Comming soon

Deicing Fluids

Preservatives

Product Information

A de-icing fluid for windscreens, carburettors and propellers. No AeroShell alternatives, but 100% isopropyl alcohol could be used as replacement.

Product information

AeroShell Compound 07 is a deicing fluid composed of ethylene glycol, isopropyl alcohol and distilled water and is used for in-flight deicing of windshields, propellers, wings, etc. on the aircraft.

AeroShell Fluid 2F is an inhibited "flyaway" lubricating oil for the internal protection of piston engines during storage.

AeroShell Fluid 2F consists of three parts AeroShell Oil 100 (SAE J-1966 Grade SAE 50) with one part AeroShell Fluid 2XN (MIL-C-6529C Type I) –a corrosion preventative.

AeroShell Fluid 2XN is a Corrosion Preventative supplied in various sizes. Specification - *MIL-C-6529 Type I.

Features:

- Can be used neat to long term storage

- Can be sprayed undiluted on piston engine exhaust ports

- Uses an ashless anti-corrosion additive package

- Has highly refined mineral based oils

AeroShell Compound 05 is a petroleum jelly/beeswax mixture for protecting metal parts against corrosion under temperate and tropical conditions.

Avionic Cooling Fluids

Product Information

AeroShell Fluid 602 is most widely used as a cooling fluid for aircraft avionic systems, whose benefits include lower initial cost, longer fluid life, lower weight and lower toxicity when compared with other types of avionic system coolants. Since AeroShell Fluid 602 does not react with water, no reclamation equipment is required, adding further to the cost advantage.

If you do not find the needed product on this page or have any questions, do not hesitate to contact us and make a further inquiry.